Inside the Design and Build of Our Newly Remodeled Hatchery

For years, we’d been dreaming about building a new hatchery but struggled to justify the cost, especially considering that the hatchery is only in use for half of the year. But after selling our main farm land and shifting away from the white bird and food products portion of our business, we found ourselves in the perfect position to upgrade.

We recently extended our existing hatchery, reimagined the layout, and invested in cutting-edge equipment to improve efficiency and biosecurity and we are excited to share that journey with you now as we are wrapping up our 2024 hatching season and prepping for the winter.

The Building & Design Process

The work on our new hatchery began in the fall of 2023 when we poured the foundation. By spring of 2024, we fully committed to redesigning the space with a focus on flow and biosecurity.

Throughout this process, we’ve been sharing pictures of the expansion. See the full gallery online here.

One of our biggest focuses was to ensure that every step in the process—from the arrival of eggs to the hatching of chicks—was seamless and safe. The new design maximized our existing area while maintaining separation between the various stages of the incubation process. This reduces the risk of contamination and helps maintain the health of our birds.

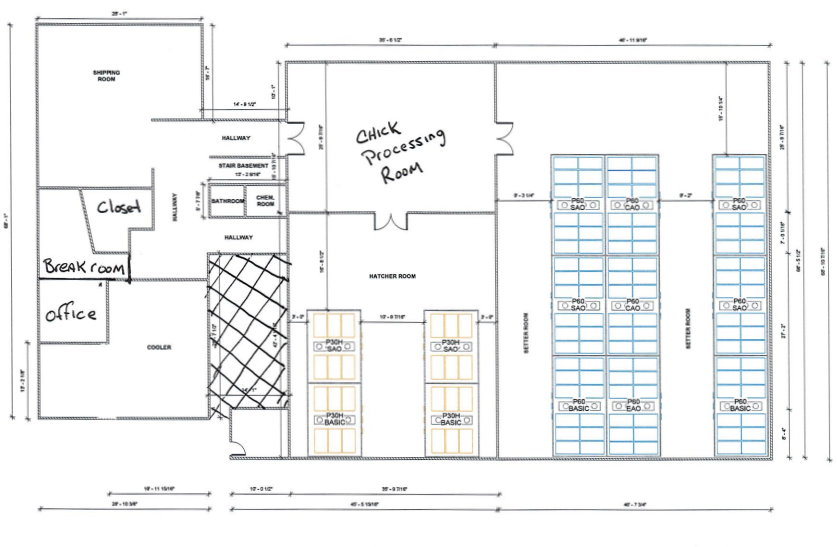

We mapped out how many new machines we’d need and retooled the layout to accommodate them. Although the original hatchery structure remains largely unchanged, we repurposed many of the rooms to improve efficiency and streamline operations. See our new hatchery layout in the image below.

Jamesway’s Cutting-Edge Equipment

In the spring of 2024, we began the installation of brand-new Jamesway incubation equipment. Transitioning from our old equipment to the new machines was a gradual process. For a few months in March and April, we operated with both old and new systems running side by side. But by the end of April, all of our equipment had been upgraded, and in May, we auctioned off our old systems to make way for a fully modernized hatchery.

Old Incubators

New Incubators

Old Hatchers

New Hatchers

Previously, with our triple-stage system, we had:

- 13 incubators,

- Each with a 21,000-egg capacity (7000 per week)

- Hatching up to 91,000 eggs weekly.

With our new single-stage system, we have:

- 9 incubators,

- Each now holds 64,512 eggs, we set 3 machines full every week

- Allowing us to hatch up to 193,500 eggs weekly.

The technology in our new hatchers is the newest incubation equipment on the market. Each machine features touch-screen controls, and we can now monitor and make remote adjustments to temperature, humidity, and CO2 levels. This precision allows us to fine-tune the environment for each batch of chicks and make real-time adjustments, even from offsite locations.

In our old system, the temperature settings were fixed, making it impossible to adjust the environment based on the developmental stage of the chicks. Now, with our single-stage system, we can tailor the conditions to ensure all chicks hatch more closely together, resulting in healthier birds and a shorter hatch window.

If the eggs are ahead or behind schedule, we can make adjustments of up to delay or speed up the hatch by up to six hours, ensuring everything is perfectly timed for shipping.

Another significant advantage of our new system is the ability to pressurize and clean each machine between hatch cycles. This wasn’t possible with our old system, and it’s already made a noticeable difference in the health of our chicks.

The Results

The improvements we’ve made to our hatchery are already showing results. In the 2024 chick season, we hatched 2.1 million chicks—an impressive increase from the 1.8 million chicks we hatched in 2023. The upgrade has allowed us to increase our production while maintaining the highest standards of quality and biosecurity.

The improvements we’ve made to our hatchery are already showing results. In the 2024 chick season, we hatched 2.1 million chicks—an impressive increase from the 1.8 million chicks we hatched in 2023. The upgrade has allowed us to increase our production while maintaining the highest standards of quality and biosecurity.

We’re excited about the future of our hatchery and confident that these changes will help us continue providing top-quality chicks for years to come.

Related Posts

A Comparison of Hatch Data Between Two Different Genetic Types of Pheasants

Read Post

Updates From MacFarlane Pheasants September 2023

Read Post

MacFarlane Pheasants, Inc. Egg Production

Read Post

Our Tips For Increasing Egg Production

Read Post

Planning Ahead for Newly Hatched Chicks

Read Post

Preparing For Egg Laying Season in Missouri

Read Post

MacFarlane Pheasants’ Hatchery-Perfecting the Conditions

Read Post

Celebrating Our New Hatchery: Official Ribbon Cutting with Forward Janesville

Read Post

Take Advantage of These Free Resources

As the biggest game bird farm in the United States, we want to share our experience with you. Download our free resources below and get started.