New Brooder Barn Construction Complete: A Major Step in Tornado Recovery

In the wake of last year’s devastating tornado, we’ve been focused on rebuilding and restoring our farm. One of the most significant steps forward has been the completion of our new brooder barn.

We approached our barn reconstruction not just as a return to normal but as an opportunity to improve our systems and upgrade our equipment for the future.

The Impact of the Tornado

When the tornado hit in June 2024, three of our four brooder barns sustained serious damage. Barn 6, in particular, was completely destroyed, while the other two were partially collapsed and badly compromised. Because Barn 6 required a complete rebuild, we were able to move more quickly into construction planning.

After prepping the site in July, we began construction and are proud to share that Barn 6 is now complete and already housing its first group of birds. Watching them grow in the new space has been rewarding, and we’re excited to see the full potential of this setup in the months ahead.

Planning The New Design

Although Barn 6 still sits on the same footprint, we increased its height from 8 feet to 10 feet. This additional space allows for more efficient cleanouts between groups of pheasants. As our pheasants grow, we move them from the A-Room in our barns to the B-Room in our barns when they are 3 weeks old. During this transition, we need to fully clean out and sanitize the A-Room before we can bring the new birds in.

With the higher ceilings, we can navigate skid loaders and other equipment more easily through the barn without concern about damaging overhead structures. This will make our sanitization process much more efficient.

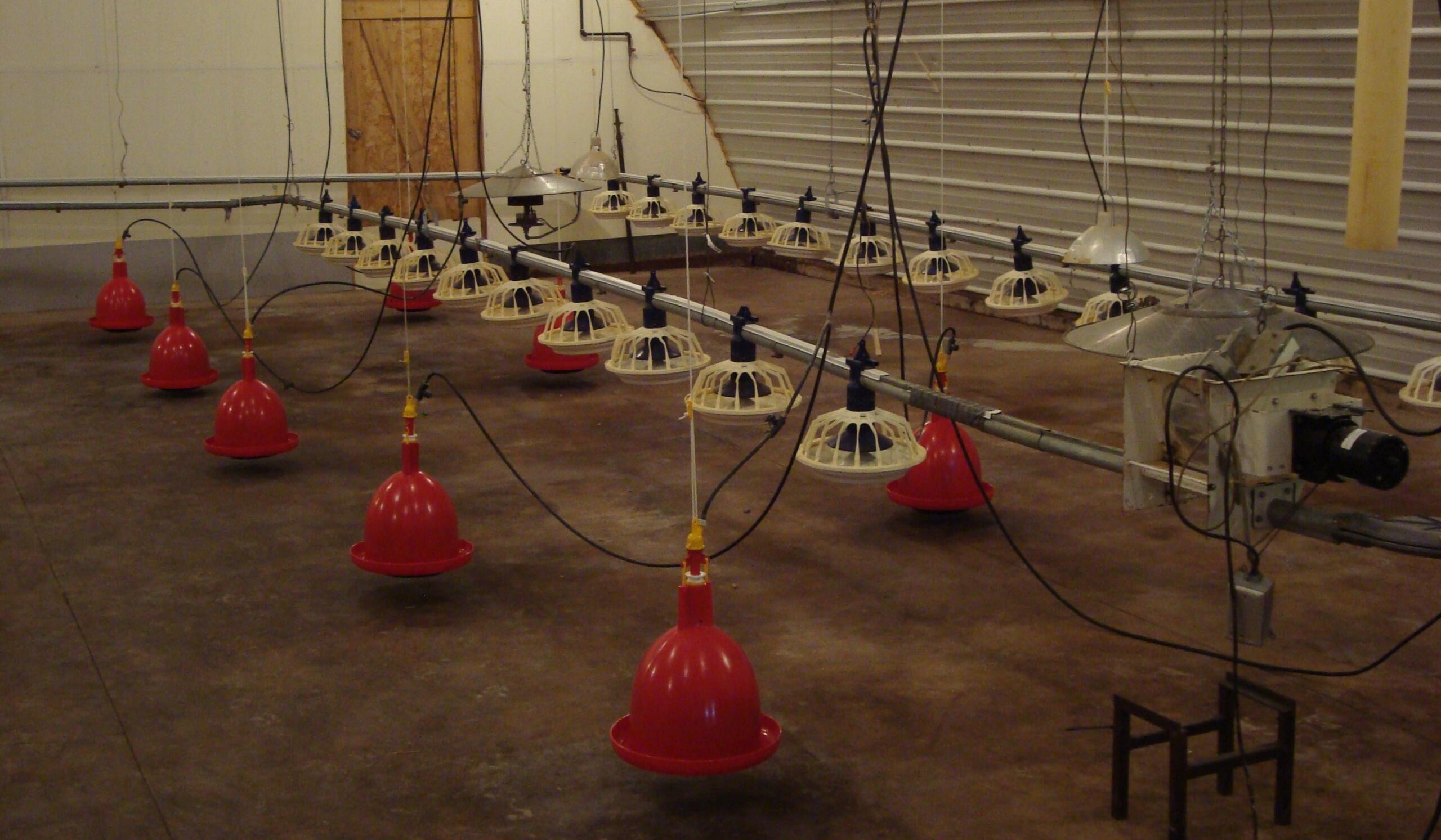

Upgraded Brooders & Fans

One of the biggest changes in Barn 6 is the introduction of a new style of brooder from LB White. We are now using the I-17 model, which features direct spark ignition. This design eliminates the need for a pilot light and is expected to help reduce fuel costs.

The barn is also equipped with new 18-inch fans to improve airflow and circulation. We’ve continued using the European Air Inlet System, which we first implemented in 2015. This system uses static pressure to evenly circulate air throughout the barn. As the fans exhaust air and create a vacuum, a controller automatically opens and closes the air inlets to optimize ventilation and prevent cold drafts. This carefully balanced process helps remove humidity and ensures our birds receive fresh, clean air.

Smarter Controls with New Technology

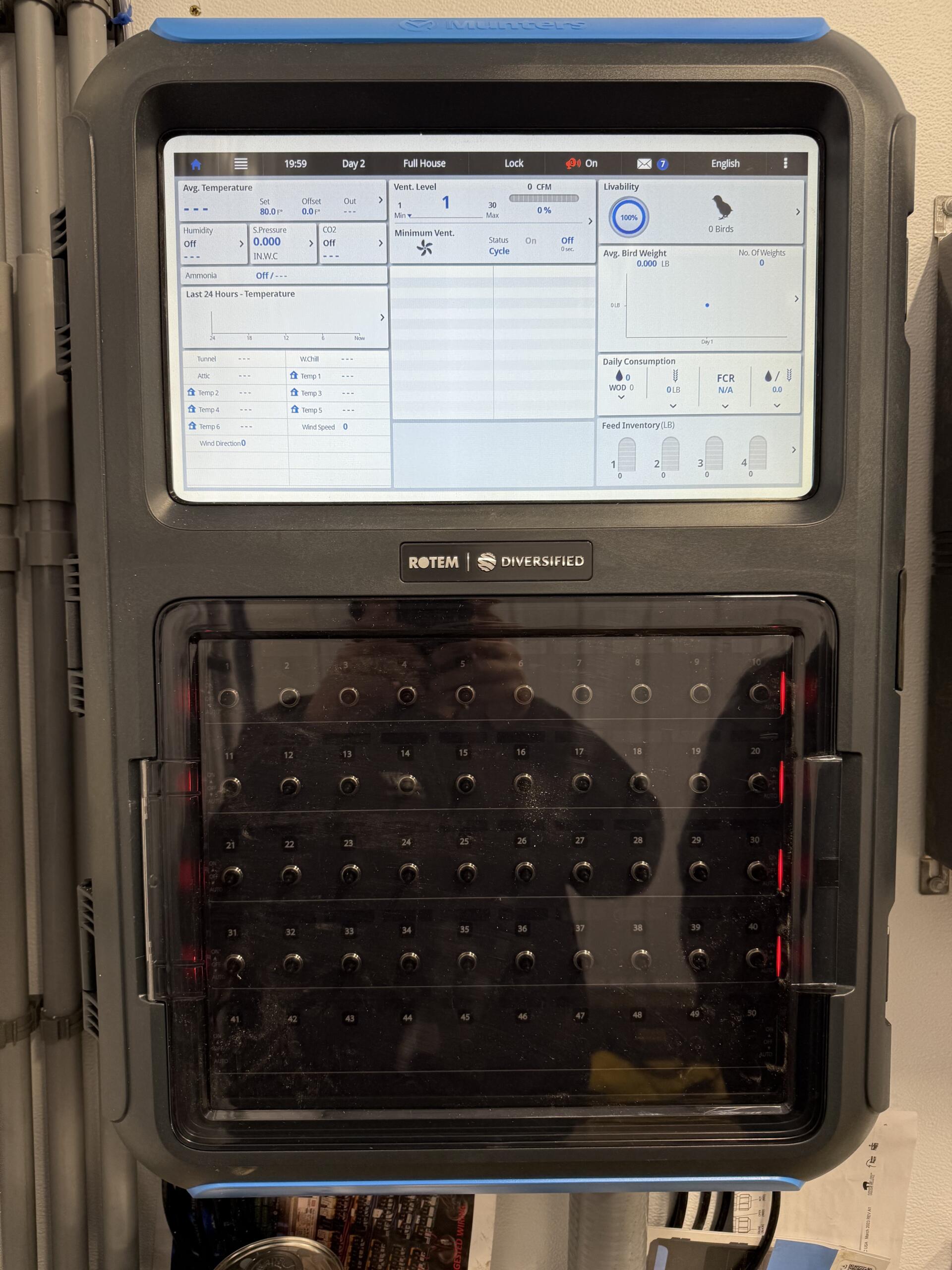

Smarter Controls with New Technology

Barn 6 also features a brand-new Rotem touchscreen controller. This advanced system gives us more precise environmental control than ever before. It can be programmed to follow a temperature curve over time, adjusting automatically as the birds grow. These gradual changes help avoid stressful temperature fluctuations and support bird health and comfort.

This is the only barn currently outfitted with this Rotem controller, which also includes remote monitoring and alarm capabilities to ensure immediate attention if any issues arise.

Looking Ahead

The first group of birds in Barn 6 is now almost ready to transition from the A-room to the B-room. We’re excited to see the new setup in action and look forward to another great year ahead.

Reconstruction of the two remaining damaged barns is underway and expected to be completed by April 21. With all three barns up and running, we’re well-positioned for a strong season ahead.

Related Posts

Preparing Our Barns & Pens Each Spring

Read Post

How We Prepare For Brooding Our Chicks

Read Post

How We Winterize at Our Milton Farm

Read Post

WI Storms and MacFarlane Pheasants

Read Post

Our Milton Farm in 2024!

Read Post

10 Ways To Get the Most Out Of Brooder Barns

Read Post

6 Feed and Water Procedures to Keep MacFarlane Pheasants Healthy

Read Post

Air Flow in Barns

Read Post

Take Advantage of These Free Resources

As the biggest game bird farm in the United States, we want to share our experience with you. Download our free resources below and get started.